Case Studies

Explore the top-notch train services completed by the team here at TBM to keep rail fleets throughout the UK rolling from depot to destination.

Northern

Seat Cover Work

Train operators are under pressure to ensure that services run on time, and Northern covers a huge geographic area that presents considerable challenges.

Something that can be controlled is the presentation of carriages. Northern approached TBM to utilise our dry-cleaning expertise that ensures that seat covers are kept clean and hygienic.

That first impression really matters to passengers and knowing that seats are safe to sit on is reassuring. It shows that the operator cares about its customers. Northern has chosen to go further, using TBM’s Fiber ProTector which creates a protective barrier on the fabric. This prevents staining and makes daily cleaning easier for the on-board cleaning teams.

Hitachi

Toilet Tanks

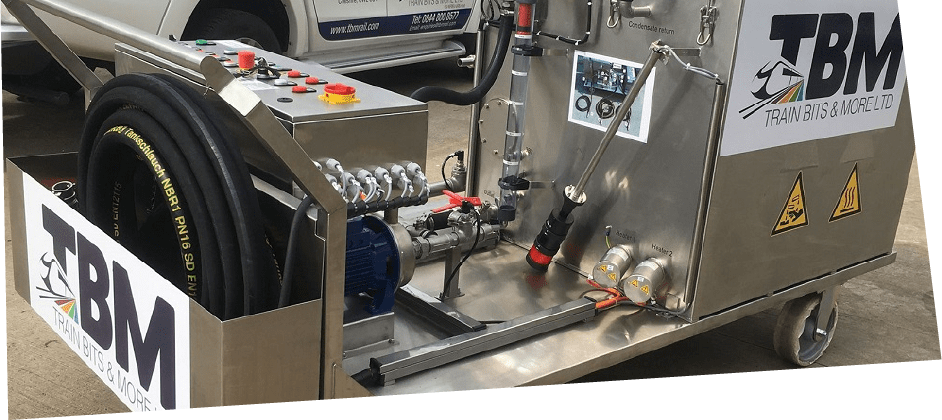

Proactive maintenance always pays dividends, and that’s exactly what Hitachi has done to support the fleets they have introduced to the UK railway network. CET (controlled emission toilet) tanks can block over time and reduce capacity.

This results in passenger toilets shutting down. From day one when Hitachi launched the impressive class 800 trains, they wanted facilities to be available for use by customers. They engaged TBM to work closely with train operators at the North Pole (GWR), Stoke Gifford (GWR), Ashford (Southeastern) and Doncaster (LNER) depots.

We supported the CET tank cleaning requirements using our mobile units. This was a firm commitment by Hitachi, as they built these regular cleaning routines into their VMI (Vehicle Maintenance Instruction).

Southern

Grab Poles with Biomaster

Grab poles and grab handles are an essential part of train and tram carriage safety. Being able to “hang on” with confidence reassures passengers.

Southern (part of GTR) recognised this and tasked TBM with coating the poles and rails throughout their Class 377 fleet of vehicles. The original specification was to use polyester coatings, but at the same time, there was a desire to find a new material that gave enhanced performance.

This led to TBM developing partnerships that created innovative nylon coating NYLON R-AG+ that also incorporates antimicrobial additives. Tough surfaces that don’t scratch or chip and help to stop the spread of germs. They even prevent most graffiti.

Mellor Coaches

Door Sensor Switches

The hop-on/hop-off nature of buses means that robust door sensor switches are essential to keep city and town services running. Mellor Coaches build vehicles that offer excellence for passengers and operators.

They needed reliable door sensor switches that work the first time, every time. TBM supplies them with technology that is good for upwards of 100,000,000 cycles before failure. It’s the perfect solution for vehicles that are in constant use and operate in a variety of challenging conditions.

The units are intuitive, look smart and are vandal-proof. They are almost indestructible. The door switches provided by TMB deliver again and again so that operators can focus on other aspects of their service.

Skip to content

Skip to content